Inkqubo yokugaya i-CNC

Ulawulo lwamanani (kwakhona ulawulo lwamanani ekhompyuter, kwaye luqhele ukubizwa ngokuba yi-CNC) lulawulo oluzenzekelayo lwezixhobo zomatshini (ezifana ne-drills, iileyile, ii-mill kunye neeprinta ze-3D) ngokusebenzisa ikhompyutha.Umatshini we-CNC usebenza iqhekeza lezinto (isinyithi, iplastiki, iplanga, i-ceramic, okanye i-composite) ukuhlangabezana neenkcukacha ngokulandela ikhowudi yomyalelo ocwangcisiweyo kwaye ngaphandle komsebenzi wezandla olawula ngokuthe ngqo ukusebenza komatshini.

Umatshini we-CNC sisixhobo esiphathwayo esinokulawulwa ngeemoto kwaye kaninzi sisixhobo esiphathwayo esisemotweni, ezilawulwa yikhompyuter zombini, ngokwemiyalelo yegalelo elithile.Imiyalelo ihanjiswa kumatshini we-CNC ngendlela yenkqubo elandelelanayo yemiyalelo yokulawula umatshini efana ne-G-code kunye ne-M-code, emva koko iqhutywe.Inkqubo inokubhalwa ngumntu okanye, rhoqo kakhulu, iveliswe yigraphical computer-aided design (CAD) software kunye/okanye computer aided production (CAM) software.Kwimeko yeeprinta ze-3D, inxalenye eza kuprintwa "yi-sliced", phambi kokuba imiyalelo (okanye iprogram) yenziwe.Iiprinta ze-3D nazo zisebenzisa i-G-Code.

I-CNC luphuculo olukhulu ngaphezu komatshini ongekho ngekhompuyutha ekufuneka ulawulwe ngesandla (umz. ukusebenzisa izixhobo ezifana namavili esandla okanye iileva) okanye ukulawulwa ngoomatshini zizikhokelo zeepateni ezenziwe kwangaphambili (iikhamera).Kwiinkqubo ze-CNC zanamhlanje, uyilo lwecandelo lomatshini kunye nenkqubo yokuvelisa i-automation ephezulu.Imilinganiselo yomatshini wenxalenye ichazwa kusetyenziswa isoftwe yeCAD kwaye emva koko iguqulelwe kwimigaqo yokwenziwa kwenkqubo yokwenziwa kwekhompyutha (CAM) software.Izikhokelo ezibangelwayo ziguqulwa (nge-software ye-"post processor") ibe yimiyalelo ethile eyimfuneko kumatshini othile ukuvelisa icandelo kwaye emva koko ilayishwe kumatshini we-CNC.

Ekubeni naliphi na icandelo elithile linokufuna ukusetyenziswa kwenani lezixhobo ezahlukeneyo – iidrili, iisarha, njl.njl. – oomatshini bale mihla badla ngokudibanisa izixhobo ezininzi kwi”seli” enye.Kolunye ufakelo, inani loomatshini abahlukeneyo basetyenziswa kunye nomlawuli wangaphandle kunye nabaqhubi babantu okanye berobhothi abahambisa icandelo ukusuka kumatshini ukuya kumatshini.Kwimeko nayiphi na into, uchungechunge lwamanyathelo afunekayo ukuvelisa nayiphi na inxalenye i-automation ephezulu kwaye ivelisa inxalenye ehambelana ngokusondeleyo nomzobo we-CAD wokuqala.

Ukugaya yinkqubo yokusika esebenzisa i-milling cutter ukususa izinto ezivela kumphezulu womsebenzi.I-milling cutter sisixhobo sokusika esijikelezayo, esihlala sineendawo ezininzi zokusika.Ngokuchasene nokugaya, apho isixhobo siqhubela phambili kunye ne-axis yayo yokujikeleza, i-cutter kwi-milling idla ngokuhanjiswa nge-perpendicular kwi-axis yayo ukwenzela ukuba ukusika kwenzeke kwi-circumference ye-cutter.Njengoko i-cutter yokugaya ingena kwindawo yokusebenza, iindawo zokusika (iifluti okanye amazinyo) zesixhobo zinqunyulwa ngokuphindaphindiweyo kwaye ziphume kwizinto eziphathekayo, ukucheba ii-chips (i-swarf) ukusuka kwindawo yokusebenza kunye nokupasa nganye.Isenzo sokusika kukucheba;Isixhobo sityhalwa siphume kwiqhekeza lomsebenzi kwizigaqana ezincinci ezijingayo ukuya kuthi ga kwinqanaba elikhulu okanye elincinci (kuxhomekeke kwizinto) ukwenza iitshiphusi.Oku kwenza ukusika kwesinyithi kwahluke ngandlel' ithile (kubuchwephesha bayo) ukusuka ekusikeni imathiriyeli ethambileyo ngencakuba.

Inkqubo yokusila isusa izinto ngokwenza ezininzi ezahlukeneyo, ukusikwa okuncinci.Oku kufezwa ngokusebenzisa umsiki onamazinyo amaninzi, ukusonta isisiki ngesantya esiphezulu, okanye ukuqhubela phambili izinto ngesixhobo sokusika ngokucothayo;amaxesha amaninzi iba yindibaniselwano yezi ndlela zintathu.[2]Izantya kunye nokutya okusetyenzisiweyo kuyahlukahlukana ukuze kuhambelane nendibaniselwano yezinto eziguquguqukayo.Isantya apho iqhekeza liqhubela phambili kwisisiki libizwa ngokuba yireyithi yokutya, okanye ukondla nje;idla ngokulinganiswa njengomgama ngexesha (i-intshi ngomzuzu [in/min okanye ipm] okanye iimilimitha ngomzuzu [mm/min]), nangona umgama nge revolution okanye izinyo lomsiki ngalinye nawo ngamanye amaxesha asetyenziswa.

Kukho iindidi ezimbini eziphambili zenkqubo yokusila:

1.Ekugayweni kobuso, isenzo sokusika senzeke ngokuyinhloko kwiikona zokugqibela ze-milling cutter.Ukugaya ubuso kusetyenziswa ukusika iindawo ezisicaba (ubuso) kwindawo yokusebenza, okanye ukusika imingxunya esezantsi.

I-2.Kwi-peripheral milling, isenzo sokusika senzeke ngokuyinhloko kunye ne-circumference of cutter, ukwenzela ukuba i-cross section ye-milled surface igqibe ukufumana imo ye-cutter.Kule meko iincakuba ze-cutter zingabonwa njengokukhupha izinto ezivela kumsebenzi wokusebenza.I-peripheral milling ifaneleka kakuhle ekusikeni iindawo zokubeka ezinzulu, imisonto, kunye namazinyo egiya.

| Umatshini weCNC | Inkcazo |

| Mill | Uguqulela iinkqubo eziquka amanani athile kunye nonobumba ukuhambisa i-spindle (okanye i-workpiece) kwiindawo ezahlukeneyo kunye nobunzulu.Abaninzi basebenzisa ikhowudi ye-G.Imisebenzi ibandakanya: ukugaya ubuso, ukuguba amagxa, ukucofa, ukugrumba kwaye abanye bade banike ukujika.Namhlanje, ii-CNC Mills zinokuba ne-3 ukuya kwi-6 axes.Uninzi lwezixhobo zokusila ze-CNC zifuna ukubeka i-workpiece kuyo okanye kuzo kwaye kufuneka ibe nkulu njengomsebenzi, kodwa oomatshini abatsha be-3-axis bayaveliswa abancinci kakhulu. |

| Lathe | Usika izixhobo zokusebenza ngelixa zijikeleziswa.Yenza ngokukhawuleza, ukusika okuchanekileyo, ngokubanzi usebenzisa izixhobo ezibonisa isalathisi kunye no-drills.Isebenza kwiinkqubo ezintsonkothileyo eziyilelwe ukwenza iinxalenye ezinokuthi zingenzeki kwiileyile zezandla.Imilinganiselo yolawulo efanayo kwi-CNC mills kwaye iyakwazi ukufunda ikhowudi ye-G.Ngokubanzi ineezembe ezimbini (X kunye no-Z), kodwa imifuziselo emitsha ineezembe ezininzi, ezivumela ukuba kwenziwe imisebenzi ephucukileyo. |

| Umsiki wePlasma | Kubandakanya ukusika imathiriyeli kusetyenziswa itotshi yeplasma.Ngokuqhelekileyo isetyenziselwa ukusika isinyithi kunye nezinye isinyithi, kodwa ingasetyenziselwa kwizinto ezahlukeneyo.Kule nkqubo, igesi (efana nomoya ocinezelweyo) ivuthelwa ngesantya esiphezulu ngaphandle kombhobho;ngelo xesha, i-arc yombane yenziwa ngaloo gesi ukusuka kwi-nozzle ukuya kumphezulu osikiweyo, ukuguqula enye yaloo gesi kwi-plasma.Iplasma ishushu ngokwaneleyo ukunyibilikisa imathiriyeli esikiweyo kwaye ihamba ngokukhawuleza ngokwaneleyo ukuvuthela isinyithi esinyibilikisiweyo kude nesikiwe. |

| Ukukhutshwa kombane ngomatshini | (EDM), eyaziwa ngokuba yi-spark machining, i-spark machining, ukutshisa, ukushona kwe-fae, okanye ukukhukuliseka kocingo, yinkqubo yokuvelisa apho ubume obufunwayo bufunyanwa kusetyenziswa ukukhutshwa kombane (iintlantsi).Izinto eziphathekayo zisuswa kwi-workpiece ngokulandelelana kokukhutshwa kwangoku ngokukhawuleza okuphindaphindiweyo phakathi kwee-electrode ezimbini, ezihlukaniswe yi-dielectric fluid kwaye zixhomekeke kumbane wombane.Enye ye-electrode ibizwa ngokuba yi-electrode yesixhobo, okanye ngokulula "isixhobo" okanye "i-electrode," ngelixa enye ibizwa ngokuba yi-electrode yomsebenzi, okanye "i-workpiece". |

| Umatshini wokusonta okuninzi | Uhlobo lomatshini wokujija osetyenziswa kwimveliso yobuninzi.Ithathwa njengesebenza kakhulu ngokunyusa imveliso ngokuzenzekela.Unokusika ngokufanelekileyo imathiriyeli ibe ngamaqhekeza amancinci ngelixa ngaxeshanye usebenzisa iseti yezixhobo ezahlukeneyo.Oomatshini bokusonta abaninzi banezijikelezo ezininzi kwigubu elijikeleza kwi-axis ethe tye okanye ethe nkqo.Igubu liqulethe intloko ye-drill equka inani leentsimbi zokuphotha ezixhonywe kwiibheringi zebhola kwaye ziqhutywa ziigiya.Kukho iintlobo ezimbini zokuqhotyoshelwa kwezi ntloko ze-drill, ezisisigxina okanye ezilungelelanisiweyo, kuxhomekeke ekubeni umgama ophakathi we-spindle yokubhoboza kufuneka uguqulwe. |

| I-EDM yocingo | Eyaziwa nangokuthi i-EDM yokusika i-wire, i-EDM yokutshisa i-wire, okanye i-EDM yocingo oluhambayo, le nkqubo isebenzisa ukutshatyalaliswa kwe-spark kumatshini okanye ukususa izinto ezivela kuyo nayiphi na into eqhuba umbane, usebenzisa i-electrode yocingo ehambayo.I-electrode yocingo ngokuqhelekileyo iqulethe izinto zobhedu okanye i-zinc-coated.I-EDM yocingo ivumela ukuba kufuphi neekona ze-90-degree kwaye ifake uxinzelelo oluncinci kakhulu kwizinto eziphathekayo.Ekubeni ucingo luchithwa kule nkqubo, umatshini we-EDM wocingo wondla ucingo olutsha kwi-spool ngelixa unqunqa ucingo olusetyenzisiweyo kwaye ulushiya emgqomeni wokuphinda usetyenziswe. |

| I-EDM yeSinker | Ekwabizwa ngokuba yi-EDM ye-cavity okanye umthamo we-EDM, i-EDM ye-sinker iqukethe i-electrode kunye ne-workpiece efakwe kwioli okanye enye i-dielectric fluid.I-electrode kunye ne-workpiece ixhunyiwe kumbane ofanelekileyo, ovelisa amandla ombane phakathi kwamacandelo amabini.Njengoko i-electrode isondela kwindawo yokusebenza, ukuphuka kwe-dielectric kwenzeka kulwelo olwenza ijelo leplasma kunye nokutsiba kwentlantsi encinci.Imveliso iyafa kwaye iimbumba zihlala zenziwe nge-EDM ye-sinker.Ezinye izinto, ezifana nezixhobo ezithambileyo zeferrite kunye ne-epoxy-rich bounded magnetic materials azihambisani ne-EDM ye-sinker njengoko ingenawo umbane.[6] |

| Umsiki wejethi yamanzi | Ikwabizwa ngokuba yi "waterjet", sisixhobo esikwaziyo ukusika kwisinyithi okanye ezinye izinto (ezifana negranite) ngokusebenzisa ijethi yamanzi ngesantya esiphezulu kunye noxinzelelo, okanye umxube wamanzi kunye nento erhawukayo, efana nesanti.Ihlala isetyenziswa ngexesha lokwenziwa okanye ukwenziwa kwamalungu oomatshini kunye nezinye izixhobo.I-Waterjet yindlela ekhethwayo xa izinto ezisikwayo zinovakalelo kubushushu obuphezulu obuveliswa zezinye iindlela.Ifumene izicelo kwinani elihlukeneyo lamashishini ukusuka kwimigodi ukuya kwi-aerospace apho isetyenziselwa imisebenzi efana nokusika, ukubunjwa, ukukrola, kunye nokuphinda kwenziwe. |

CNC ukomba

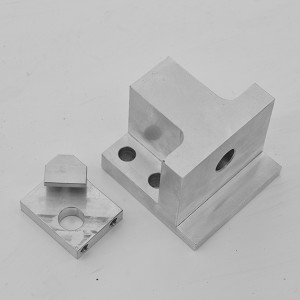

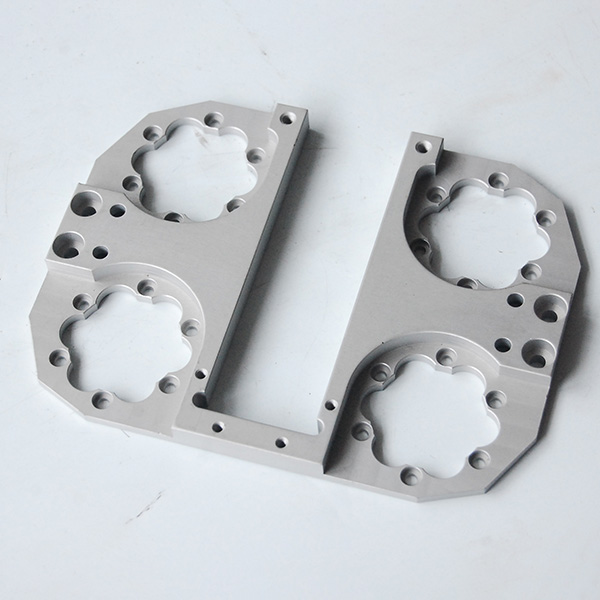

iinxalenye

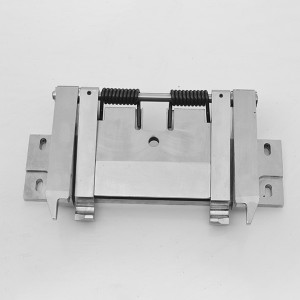

CNC ngoomatshini

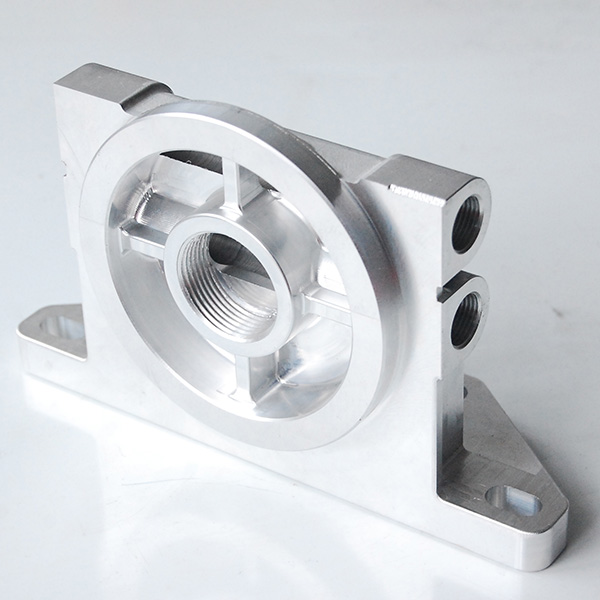

amalungu aluminiyam

CNC Machining

iindawo ezigobileyo

CNC Machining iindawo

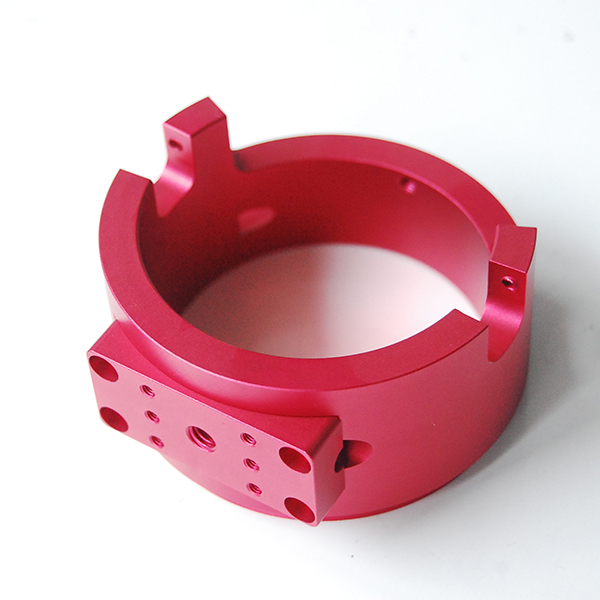

nge anodizing

Ukuchaneka okuphezulu

iindawo zecnc

Ukuphoswa kwe-aluminiyam echanekileyo

ngoomatshini kunye ne-anodized

I-aluminiyam echanekileyo

ngoomatshini

Intsimbi cnc

iindawo zomatshini