Inkqubo yesitampu

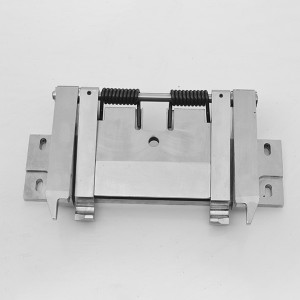

Isitampu (ekwabizwa ngokuba kukucinezela) yinkqubo yokubeka isinyithi esisicaba nokuba kungenanto okanye kwifomu yekhoyili kwisitampu sokushicilela apho isixhobo kunye nomphezulu wokufa zenza isinyithi sibe kwimilo yenethi.Isitampu sibandakanya iindlela ezahlukeneyo zokwenza i-sheet-metal forming process, ezifana nokubetha ngenqindi kusetyenziswa umatshini wokushicilela okanye ukucofa isitampu, ukuvala umlomo, ukufaka imbossing, ukugoba, ukugoba, kunye nokudibanisa.Oku kunokuba ngumsebenzi wenqanaba elinye apho yonke i-stroke yoshicilelo ivelisa ifom efunwayo kwiphepha lentsimbi, okanye inokwenzeka ngoluhlu lwezigaba.Inkqubo idla ngokuqhutyelwa kwiphepha lesinyithi, kodwa ingasetyenziselwa kwezinye izinto, ezifana ne-polystyrene.I-Progressive dies idla ngokutyiswa ukusuka kwikhoyili yentsimbi, i-coil reel yokukhulula ikhoyili ukuya kwi-straightener ukulinganisa ikhoyili kunye ne-feeder eqhubela phambili imathiriyeli kushicilelo kwaye ife kubude besondlo obumiselweyo.Ngokuxhomekeke kubunzima benxalenye, inani lezikhululo kwidayiti linokumiselwa.

Ukunyathela ngokuqhelekileyo kwenziwa kwiphepha lentsimbi elibandayo.Jonga ukwenza imisebenzi yentsimbi eshushu.

Intsimbi engatyiwa: SS304, SS304L, SS316, SS316L, SS303, SS630

Intsimbi yeCarbon: 35CrMo, 42CrMo, ST-52, Ck45, intsimbi ye-alloy;ST-37, S235JR, C20, C45, 1213, 12L14 carbon steel;

Ingxubevange yobhedu: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

I-aluminium ingxubevange: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

1. Ukugoba - izinto eziphathekayo zikhubazekile okanye zigobe ngomgca othe ngqo.

2. I-Flanging - i-material igotywe ngomgca ogobileyo.

3. I-Embossing - i-material yoluliwe ibe yintlupheko enzulu.Isetyenziselwa ikakhulu ukongeza iipatheni zokuhlobisa.

4. Ukuvala - isiqwenga sinqunyulwa kwiphepha lezinto eziphathekayo, ngokuqhelekileyo ukwenza indawo engenanto ukuze kuqhutywe phambili.

5. I-Coining - ipateni ixinzelelwe okanye igxininiswe kwizinto eziphathekayo.Ngokwemveli yayisetyenziselwa ukwenza iingqekembe.

6. Umzobo - indawo engenanto yoluliwe ibe yimilo eyenye ngokuhamba kwezinto ezilawulwayo.

7. Ukolula - indawo engaphezulu kwendawo engenanto yongezwa ngoxinzelelo, kungekho ntshukumo yangaphakathi yomgca ongenanto.Idla ngokusetyenziswa ukwenza amalungu omzimba agudileyo.

8. I-Ayina - izinto eziphathekayo zicinezelwe kwaye zincitshiswe ngobunzima kunye nodonga oluthe nkqo.Isetyenziselwa iitoti zesiselo kunye neekesi zeekhatriji zembumbulu.

9. Ukunciphisa / I-Necking - esetyenziselwa ukunciphisa ngokuthe ngcembe ububanzi besiphelo esivulekileyo somkhumbi okanye ityhubhu.

10. I-Curling - i-deforming material ibe yiprofayili ye-tubular.Iihenjisi zamacango ngumzekelo oqhelekileyo.

11. Ukusonga i-edge phezu kwayo ukongeza ubukhulu.Imiphetho yeengcango zemoto idla ngokuba ngumjikelo.

Ukugqobhoza nokusikwa kunokwenziwa nakumatshini wokushicilela.Isitampu esiqhubelekayo yindibaniselwano yezi ndlela zingentla zenziwe ngeseti yeedies emgceni apho umcu wemathiriyeli udlula inyathelo elinye ngexesha.

Ukwenza mnyama iindawo ezinesitampu

Inkqubo yesitampu

Intsimbi ebandayo yamacandelo